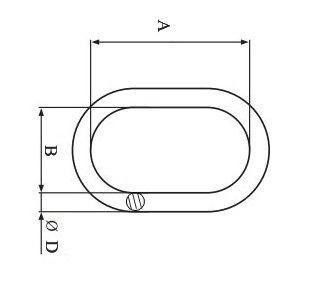

Detailed Specification

Material: Forged supper alloy steel,Quenched and Tempered. Surface Treatment: Powder Coated Individually proof test at 2 times working load limit. Ultimate Load is 5 times the Working Load Limit.Based on single leg sling (in-line load),or resultant load multiple legs with an included angle less than or equal to 120 degrees. 100% Magnetic crack detection.

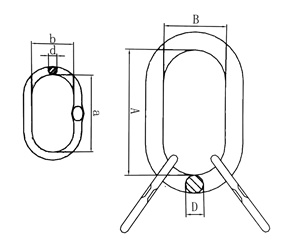

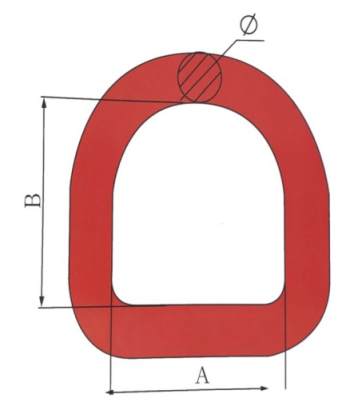

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

||

|---|---|---|---|---|---|

| A | B | D | |||

| 1/2 | 127.00 | 63.5 | 14.00 | 3.20 | 0.45 |

| 5/8 | 152.00 | 76 | 16.00 | 4.10 | 0.7 |

| 3/4 | 140.00 | 70 | 19.00 | 5.60 | 1 |

| 7/8 | 160.00 | 90 | 22.00 | 6.80 | 1.5 |

| 1 | 178.00 | 89 | 25.00 | 11.00 | 2.06 |

| 1-1/4 | 220.00 | 110 | 32.00 | 16.40 | 1.23 |

| 1-1/2 | 267.00 | 135 | 38.00 | 24.60 | 7.5 |

| 1-3/4 | 305.00 | 152 | 45.00 | 38.50 | 11.5 |

| 2 | 355.00 | 178 | 51.00 | 46.50 | 16.5 |

| 2-1/4 | 406.00 | 203 | 57.00 | 64.90 | 24.5 |

| 2-1/2 | 406.00 | 203 | 63.50 | 72.60 | 31 |

| 2-3/4 | 406.00 | 240 | 70.00 | 98.40 | 41 |

| 3 | 456.00 | 228 | 76.00 | 103.40 | 52 |

| 3-1/4 | 508.00 | 254 | 82.00 | 119.00 | 66 |

| 3-1/2 | 610.00 | 305 | 89.00 | 126.50 | 91 |

| 3-3/4 | 508.00 | 254 | 95.00 | 152.40 | 90 |

| 4 | 508.00 | 254 | 100.00 | 169.20 | 103.5 |

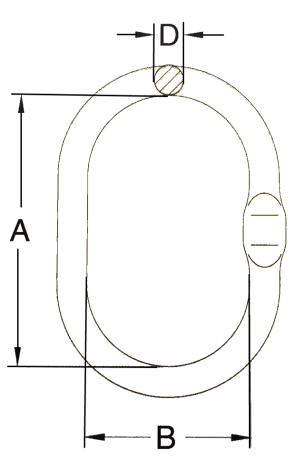

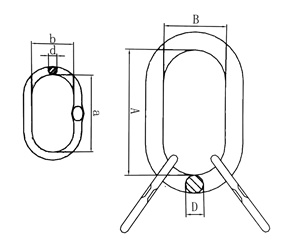

Standard:EN1677-4 (Supersedes DIN5688-3)

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2.5 times working load limit.

Ultimate Load is 5 times the Working Load Limit.Based on single leg

sling (in-line load),or resultant load multiple legs with an included angle

less than or equal to 120 degrees.

100% Magnetic crack detection.

| Size (inch) |

G80 EN818-2 Chain |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

|||

|---|---|---|---|---|---|---|---|

| For 1 Leg | For 2 Leg | A | B | D | |||

| 76-8 | 7 | 6 | 110 | 60 | 14 | 1.6 | 0.4 |

| 87-8 | 8 | 7 | 110 | 60 | 16 | 2.2 | 0.54 |

| 108-8 | 10 | 8 | 135 | 75 | 18 | 3.15 | 0.82 |

| 1310-8 | 13 | 10 | 160 | 90 | 22 | 5.3 | 1.5 |

| 1613-8 | 16 | 13 | 180 | 100 | 25 | 8 | 2.13 |

| 1816-8 | 18 | 16 | 200 | 110 | 32 | 11.2 | 3.95 |

| 2018-8 | 20 | 18 | 260 | 140 | 36 | 14 | 6.33 |

| 2220-8 | 22 | 20 | 300 | 160 | 40 | 17 | 9.0 |

| 2622-8 | 26 | 22 | 340 | 180 | 45 | 21.2 | 12.8 |

| 3226-8 | 32 | 26 | 350 | 190 | 50 | 31.5 | 17.2 |

| 3632-8 | 36 | 32 | 400 | 200 | 56 | 45 | 24.2 |

| 4036-8 | 40 | 36 | 430 | 220 | 63 | 56 | 32 |

| 4540-8 | 45 | 40 | 460 | 250 | 72 | 63 | 46 |

| 80 | - | 45 | 500 | 270 | 80 | 85.46 | 62 |

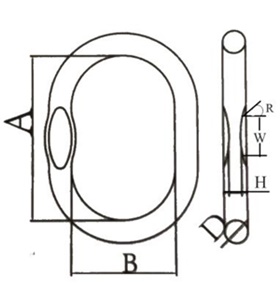

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection.

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

|||||

|---|---|---|---|---|---|---|---|---|

| A | B | D | W | H | R | |||

| 7/16 | 100.00 | 60 | 12.00 | 25.00 | 6.00 | 45.00 | 1.20 | 0.27 |

| 1/2 | 100.00 | 60 | 14.00 | 25.00 | 7.50 | 45.00 | 2.20 | 0.38 |

| 11/16 | 160.00 | 90 | 18.00 | 35.00 | 8.50 | 45.00 | 5.20 | 1 |

| 3/4 | 160.00 | 90 | 20.00 | 45.00 | 10.40 | 45.00 | 6.50 | 1.2 |

| 7/8 | 180.00 | 100 | 22.00 | 45.00 | 13.50 | 45.00 | 9.20 | 1.62 |

| 1 | 180.00 | 100 | 25.00 | 16.50 | 45.00 | 9.40 | 2.13 | |

| 1-1/8 | 270.00 | 140 | 28.00 | 16.50 | 45.00 | 12.80 | 3.8 | |

| 1-1/4 | 270.00 | 140 | 32.00 | 18.50 | 45.00 | 17.00 | 5.1 | |

For chain sling minimum Ultimate Load is 4 times working load limit.

For steel rope sling minimum ultimate load is 5 times working load limit.

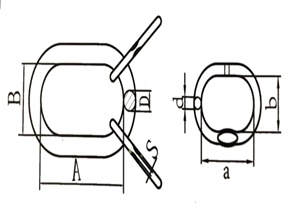

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection. Main link is forged,Sub link welded. The pressing flat for use OMEGA LINK and there will be processing flat only on requested.

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

|||||

|---|---|---|---|---|---|---|---|---|

| A | B | D | a | b | d | |||

| 3/7 | 140.00 | 70 | 20.00 | 85.00 | 40.00 | 14.00 | 4.20 | 1.67 |

| 7/8 | 160.00 | 95 | 22.00 | 85.00 | 40.00 | 14.00 | 5.30 | 2.2 |

| 1 | 178.00 | 89 | 25.00 | 100.00 | 60.00 | 18.00 | 8.00 | 3.29 |

| 1-1/4 | 220.00 | 110 | 32.00 | 100.00 | 60.00 | 22.00 | 14.00 | 6.3 |

| 1-1/2 | 267.00 | 135 | 38.00 | 180.00 | 100.00 | 30.00 | 21.20 | 13.7 |

| 1-3/4 | 305.00 | 152 | 45.00 | 180.00 | 100.00 | 32.00 | 30.00 | 21.25 |

| 2 | 356.00 | 178 | 50.00 | 180.00 | 100.00 | 38.00 | 39.40 | 30.34 |

| 2-1/4 | 406.00 | 203 | 57.00 | 180.00 | 100.00 | 45.00 | 45.00 | 39.87 |

| 2-1/2 | 406.00 | 203 | 64.00 | 355.00 | 178.00 | 50.00 | 55.50 | 64.4 |

| 2-3/4 | 406.00 | 241 | 70.00 | 406.00 | 203.00 | 57.00 | 63.00 | 89 |

| 3 | 457.00 | 228 | 76.00 | 406.00 | 203.00 | 64.00 | 70.00 | 112.14 |

For chain sling minimum Ultimate Load is 4 times working load limit.

For steel rope sling minimum ultimate load is 5 times working load limit.

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection. Main link is forged,Sub link welded. Without processing flat will be DIN5688

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

|||||

|---|---|---|---|---|---|---|---|---|

| A | B | D | a | b | d | |||

| 6-8 | 135.00 | 75 | 18.00 | 54.00 | 25.00 | 14.00 | 2.36 | 1.18 |

| 7-8 | 135.00 | 75 | 18.00 | 60.00 | 38.00 | 13.00 | 3.15 | 1.24 |

| 8-8 | 160.00 | 90 | 22.00 | 70.00 | 34.00 | 16.00 | 5.30 | 2.2 |

| 10-8 | 180.00 | 100 | 26.00 | 85.00 | 40.00 | 18.00 | 6.70 | 3.21 |

| 13-8 | 200.00 | 110 | 32.00 | 115.00 | 50.00 | 22.00 | 11.20 | 6 |

| 16-8 | 260.00 | 140 | 36.00 | 140.00 | 65.00 | 25.00 | 17.00 | 9.96 |

| 18-8 | 340.00 | 180 | 45.00 | 180.00 | 110.00 | 32.00 | 21.20 | 20 |

| 20-8 | 350.00 | 190 | 50.00 | 180.00 | 110.00 | 32.00 | 31.50 | 24 |

| 22-8 | 400.00 | 200 | 56.00 | 300.00 | 160.00 | 40.00 | 40.00 | 41.4 |

| 26-8 | 430.00 | 220 | 63.00 | 340.00 | 180.00 | 45.00 | 50.00 | 57.6 |

| 32-8 | 160.00 | 250 | 72.00 | 350.00 | 190.00 | 50.00 | 63.00 | 79 |

For chain sling minimum Ultimate Load is 4 times working load limit.

For steel rope sling minimum ultimate load is 5 times working load limit.

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection.

Main link is welded,Sub link welded.

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

|||||

|---|---|---|---|---|---|---|---|---|

| A | B | D | a | b | d | |||

| 1/2 | 100.00 | 60 | 14.00 | 85.00 | 40.00 | 12.00 | 2.40 | 0.83 |

| 11/16 | 160.00 | 90 | 18.00 | 100.00 | 60.00 | 14.00 | 3.20 | 1.76 |

| 3/4 | 160.00 | 90 | 20.00 | 100.00 | 60.00 | 14.00 | 5.00 | 1.96 |

| 7/8 | 180.00 | 100 | 220.00 | 150.00 | 70.00 | 18.00 | 8.00 | 3.25 |

| 1-1/8 | 270.00 | 140 | 28.00 | 160.00 | 90.00 | 22.00 | 12.00 | 6.74 |

| 1-1/4 | 270.00 | 140 | 32.00 | 180.00 | 100.00 | 25.00 | 17.40 | 9.31 |

| 1-1/2 | 300.00 | 160 | 40.00 | 270.00 | 140.00 | 32.00 | 21.00 | 19.1 |

| 1-3/4 | 340.00 | 180 | 45.00 | 285.00 | 155.00 | 36.00 | 30.00 | 36.6 |

| 2 | 350.00 | 190 | 50.00 | 340.00 | 180.00 | 45.00 | 40.00 | 42.9 |

For chain sling minimum Ultimate Load is 4 times working load limit.

For steel rope sling minimum ultimate load is 5 times working load limit.

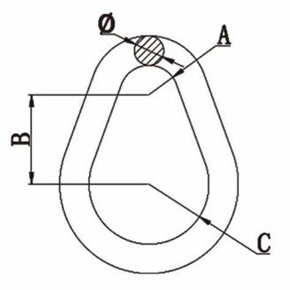

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection.

Ultimate Load is 4 times working load limit.

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

|||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 3/8 | 10.00 | 28.5 | 19.00 | 10.00 | 1800 | 0.1 |

| 1/2 | 12.50 | 38 | 25.50 | 12.50 | 7000 | 0.25 |

| 5/8 | 16.00 | 47.5 | 32.00 | 16.00 | 9000 | 0.5 |

| 3/4 | 19.00 | 57 | 38.00 | 19.00 | 12300 | 0.8 |

| 7/8 | 22.00 | 67 | 44.50 | 22.00 | 14000 | 1.4 |

| 1 | 25.00 | 76 | 51.00 | 25.00 | 24360 | 1.9 |

| 1-1/8 | 28.00 | 86 | 57.00 | 28.50 | 30600 | 2.92 |

| 1-1/4 | 32.00 | 95 | 63.50 | 31.50 | 36000 | 3.75 |

| 1-3/8 | 350.00 | 105 | 70.00 | 35.00 | 43000 | 5.12 |

| 1-1/2 | 38.00 | 114 | 76.00 | 38.00 | 54300 | 6.5 |

| 1-5/8 | 41.50 | 124 | 82.50 | 41.30 | 62600 | 8.4 |

| 1-3/4 | 44.50 | 133 | 89.00 | 44.50 | 84900 | 10.21 |

| 1-7/8 | 48.00 | 143 | 95.50 | 47.60 | 95800 | 13.15 |

| 2 | 51.00 | 152.5 | 102.00 | 51.00 | 102600 | 15.4 |

| 2-1/4 | 57.50 | 171.5 | 114.50 | 57.00 | 143100 | 21.78 |

| 2-1/2 | 63.50 | 190.5 | 127.00 | 63.50 | 147300 | 29.94 |

| 2-3/4 | 70.00 | 209.5 | 140.00 | 70.00 | 216900 | 39.92 |

| 3 | 76.50 | 229 | 152.50 | 76.00 | 228000 | 51.71 |

| 3-1/4 | 82.50 | 248 | 165.00 | 82.50 | 262200 | 66.2 |

| 3-1/2 | 89.00 | 257.5 | 178.00 | 89.00 | 279000 | 82.1 |

| 4 | 102.00 | 305 | 203.50 | 101.50 | 373000 | 122.93 |

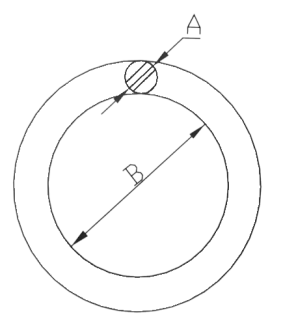

Forged Weldless Round Ring

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection.

Ultimate Load is 6 times working load limit.

| Dimensions (AXB) | WLL (T) | Weight ( kg ) |

|---|---|---|

| 3/8 x 2 | 1100.00 | 0.11 |

| 1/2 x 2 | 2200.00 | 0.23 |

| 5/8 x 3 | 3300.00 | 0.46 |

| 5/8 x 3 5/16 | 3300.00 | 0.5 |

| 3/4 x 3 | 5000.00 | 0.75 |

| 3/4 x 4 | 5600.00 | 1.1 |

| 7/8 x 4 | 7200.00 | 1.4 |

| 7/8 x 5-1/2 | 5600.00 | 1.9 |

| 1 x 4 | 10800.00 | 1.8 |

| 1 x 5-1/2 | 10800.00 | 2.3 |

| 1-1/8 x 6 | 10400.00 | 2.8 |

| 1-1/4 x 5 | 17000.00 | 3.5 |

| 1-1/4 x 6 | 17000.00 | 4.2 |

| 1-1/4 x 10 | 17000.00 | 6.2 |

| 1-3/8 x 6 | 19000.00 | 5.0 |

| 1-1/2 x 8 | 25000.00 | 7.3 |

| 1-1/2 x 10 | 25000.00 | 8.4 |

| 2 x 12 | 35000.00 | 18.2 |

Material: Alloy steel,Quenched and Tempered.

Surface Treatment: Powder Coated

Individually proof test at 2 times working load limit.

100% Magnetic crack detection.

All size are forged.

Ultimate Load is 4 times working load limit.

| Size (inch) |

Dimensions ( mm ) |

WLL (T) |

Weight (kg) |

||

|---|---|---|---|---|---|

| A | B | D | |||

| 14 | 55.00 | 65 | 14.00 | 1.50 | 0.4 |

| 18 | 55.00 | 65 | 18.00 | 2.00 | 0.6 |

| 20 | 72.00 | 80 | 20.00 | 3.00 | 9000 |

| 22 | 75.00 | 92.5 | 22.00 | 4.00 | 1.1 |

| 25 | 80.00 | 100 | 25.00 | 5.00 | 1.6 |

| 28 | 90.00 | 110 | 28.00 | 8.00 | 2.15 |

| 30 | 100.00 | 125 | 30.00 | 10.00 | 2.75 |

| 32 | 110.00 | 135 | 32.00 | 15.00 | 3.38 |

BROCHURES

View our brochure for an easy to read guide on all of the products offer.