The FGM500 Rail Milling Train integrates high-speed milling and flexible grinding. It can not only perform repair milling and grinding for defects such as spalling, fat edge, fish scale pattern and side grinding of rails, but also realize preventive scientific grinding and pre-grinding before new line opening. The product has excellent wave grinding repair ability and contour processing accuracy, and defects can be completely eliminated in one pass.

The products are clean, efficient, lightweight and intelligent, with completely independent intellectual property rights and world-leading technology. It can provide timely maintenance services, cost-effective parts supply, rapid profile customization and all-round operation and maintenance services

FGM500 rail milling train has five competitive advantages – “new, small, fast, clean and inexpensive”.

“New” – the first core technology in China, with independent intellectual property rights

“Small” – light device, easy to transport

“Fast” – fast work efficiency and high contour accuracy

“Clean” – high collection rate of iron filings and little environmental pollution

“Inexpensive” – Significantly reduce procurement costs and operating costs.

“New” – the first core technology in China, with independent intellectual property rights

“Small” – light device, easy to transport

“Fast” – fast work efficiency and high contour accuracy

“Clean” – high collection rate of iron filings and little environmental pollution

“Inexpensive” – Significantly reduce procurement costs and operating costs.

FGM500 rail milling train integrates domestic and foreign advanced technologies such as high-efficiency and high-precision tool technology, intelligent control technology, high-precision and high-response detection technology, combined with the design experience of the company’s design and development team in the field of rail maintenance, using lightweight, The intelligent and modular design idea has been optimized and upgraded on the basis of the FGM01 train, which is deeply loved by users.

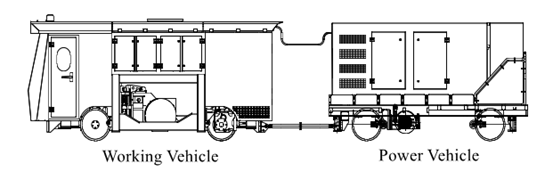

The whole vehicle consists of two sections, divided into a working vehicle and a power vehicle.

The two vehicles are formed into a fixed group by rigid connecting rods. The overall dimensions (length x width x height) are: 9390mm x 2200mm x 2120mm, and the curb weight is 15 tons.

The two vehicles are formed into a fixed group by rigid connecting rods. The overall dimensions (length x width x height) are: 9390mm x 2200mm x 2120mm, and the curb weight is 15 tons.

The work vehicle is a complete work unit without power, including the milling and grinding device and its control system, chip collection device, driver’s cab, etc.

The power vehicle mainly provides power for the running of the whole train, milling and grinding operations and other auxiliary electrical equipment, and also has the function of rail grinding.

The power vehicle mainly provides power for the running of the whole train, milling and grinding operations and other auxiliary electrical equipment, and also has the function of rail grinding.

More detailed, kindly contact us at sales@maxpluspro.com

BROCHURES

View our brochure for an easy to read guide on all of the products offer.